RAMS (Rack Asset Management System) is a technology-driven solution designed to optimize warehouse safety, efficiency, and compliance. Using Digital

Twin technology, real-time monitoring, and IoT integration, RAMS transforms traditional warehouse management into a data-driven, automated process.

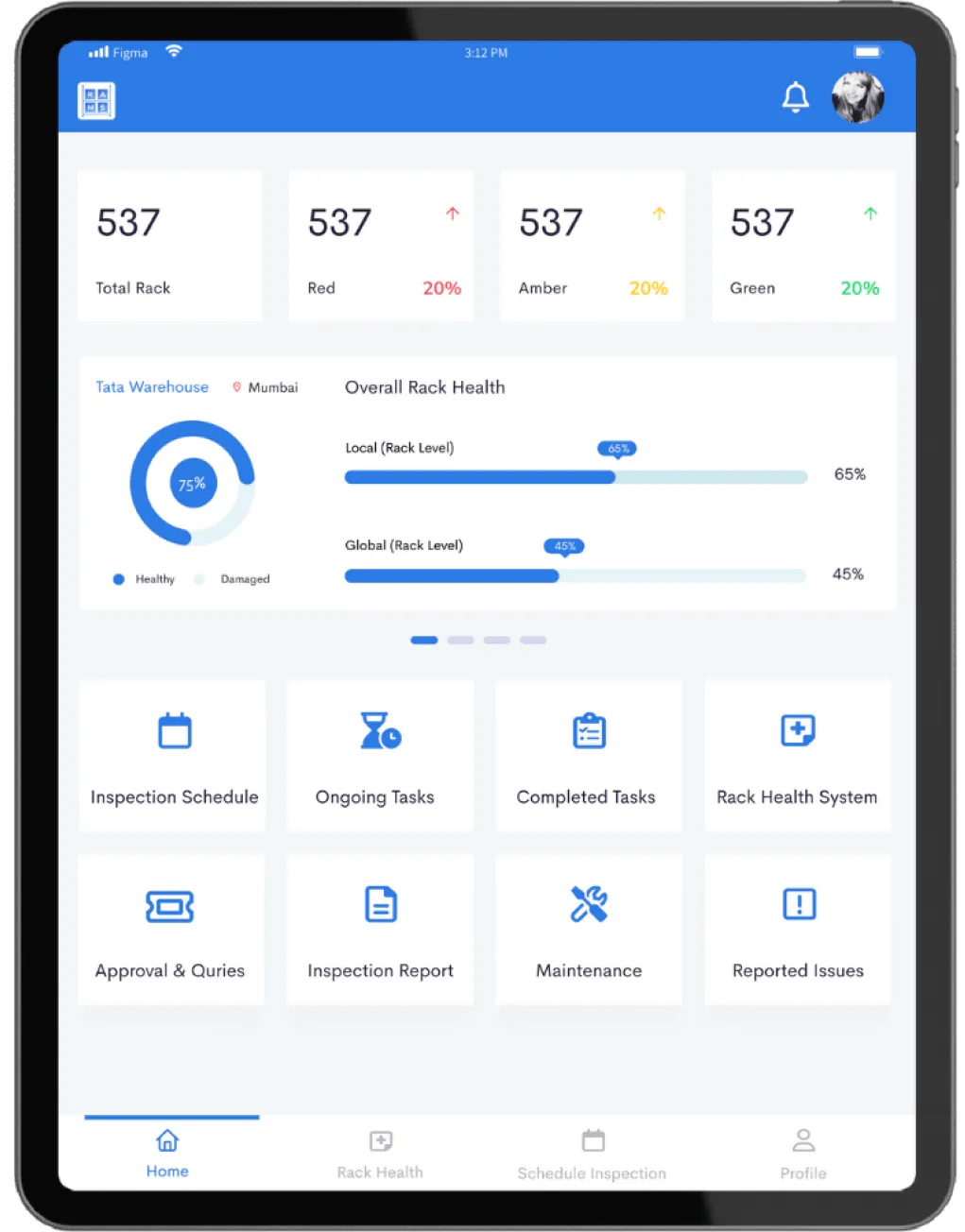

RAMS is fully digital rack management software that allows you to monitor the safety of your racks anytime, anywhere.

It provides you with a real-time tracking and monitoring portal for your pallet racking inspections, damage, or repairs and easily and efficiently optimizes the overall safety of your warehouse.

It gives you the control, visibility, reporting, and traceability you need to keep your warehouse safe.

RAMS provides a complete view of your warehouse estate, enabling you to save time and money and improve rack safety.

Leveraging real-time information from a central cloud interface makes RAMS a truly revolutionary portal for managing your warehouses.

Get a Real-time admin dashboard to maintain your rack safety and monitor all your warehouse operations all in one place.

This Safety Management portal doesn’t neglect even the smallest pallet racking issue, which ultimately aids in your personnel’ attaining the highest level of rack health.

RAMS provides the necessary solution for ensuring that the respective authority regularly inspects your rack system, and it also keeps all records of inspections and their results

The Integrated Rack Diagnostic Suite (IRDS) is a state-of-the-art tool designed to revolutionise warehouse management.

IRDS is tailored for both internal and external audits.

It automates the auditing process, tracks maintenance needs, and offers visual tools to pinpoint rack issues.

It enhances safety, optimises operational efficiency, and ensures compliance across the board.

The Mobile Equipment Positioning Suite (MEPS) is a critical tool within RAMS designed to optimise the movement and utilisation of material handling equipment (MHE).

MEPS delivers real-time tracking and data analysis to improve route optimisation, reduce equipment wear and tear, and ensure safe operation.

MEPS helps streamline warehouse operations and boost productivity by automating task assignments and equipment usage.

The Real-Time Safety Suite (RTSS) is a critical component of RAMS, designed to monitor and improve safety across warehouse operations.

By integrating real-time tracking, impact detection, and behaviour analysis, RTSS helps identify potential safety risks before they escalate.

With automated alerts and preventive measures, RTSS empowers warehouse managers to ensure a safe working environment while minimising downtime and reducing accident-related costs.

Because we understand how important Pallet Racking Safety is to you as a business owner, we take great pride in putting your needs at the forefront.

We will be with you right from the onboarding up until you achieve the optimum Rack-Health for your warehouse.

We specialize in solving the complex issues associated with pallet rack systems.

Optimize Your Storage Capacity

Whether you’re looking to maximize your storage space or streamline your inventory management, our expert solutions are designed to help you achieve optimal storage capacity. RAMS includes tools that can transform your warehouse into a model of efficiency.

Enhance Safety Standards

Safety is our top priority. We understand the critical importance of maintaining a safe working environment, and comprehensive inspection services ensure that your racking systems comply with the highest safety standards. By identifying potential hazards and providing actionable solutions, RAMS helps you prevent accidents and maintain a safe workplace.

Ensure Compliance with Industry Regulations

Navigating the complexities of industry regulations can be challenging. PRMS provides expert guidance to ensure your racking systems meet all relevant compliance requirements.

RAMS ensures thorough inspections and detailed reports keep you informed and prepared for any regulatory audits.

Join a community of industry professionals dedicated to excellence in pallet racking management. Share insights, discuss best practices, and stay updated on the latest industry trends. Our collaborative network is here to support you.

Planning for the future is essential for sustainable success.

At PRMS, we help you anticipate challenges and prepare for growth with forward-thinking solutions tailored to your specific needs.

With RAMS, you can easily monitor and analyze the condition of your racks, identify potential problems before they occur, and schedule maintenance and repairs at the most convenient times. This proactive approach ensures your operations run smoothly, protecting both your inventory and workers.

RAMS offers a comprehensive pallet racking safety management tool that digitizes inspections. Easily schedule and conduct inspections, track progress, and generate detailed reports. Whether online or offline, our platform provides you with real-time data, enabling informed decisions about your racking system.

RAMS can be used to provide advanced impact detection capabilities, allowing you to track and monitor impacts on your pallet rack system in real time. This feature provides detailed analyses of impact locations and causes, enabling you to promptly address any issues and prevent catastrophic damage.

With RAMS, you gain full control over your warehouse racking, from inspections to repairs. This powerful tool lets you easily schedule and manage racking inspections, monitor rack conditions in real time, and ensure your racking system is always in top condition and compliant with industry regulations.

RAMS offers a comprehensive pallet racking safety management tool that digitizes inspections. Easily schedule and conduct inspections, track progress, and generate detailed reports. Whether online or offline, our platform provides you with real-time data, enabling informed decisions about your racking system.

RAMS can be used to provide advanced impact detection capabilities, allowing you to track and monitor impacts on your pallet rack system in real time. This feature provides detailed analyses of impact locations and causes, enabling you to promptly address any issues and prevent catastrophic damage.

RAMS supports a multi-user environment with distinct roles to streamline warehouse operations and enhance safety protocols. The platform allows for precise role-based access, ensuring that each user only interacts with relevant data and functions tailored to their responsibilities. Managers can oversee the entire system, third-party inspectors (TPIs) conduct thorough inspections, and regular users handle day-to-day tasks.

RAMS leverages advanced analytics to provide users with actionable insights, helping to optimize warehouse operations and enhance safety measures. The platform collects and analyzes data from various sources, offering detailed reports and predictive analytics.

RAMS helps ensure your operations comply with the latest industry regulations, including FEM and AS4084:2023 standards. The platform provides tools and resources to maintain compliance and avoid costly fines. Automated Compliance Checks: Perform automated checks to ensure all safety standards are met. Detailed Compliance Reports: Generate comprehensive reports for regulatory audits