The Integrated Rack Diagnostic Suite (IRDS) combines cutting-edge technology with real-time data analysis to ensure your warehouse operates at its safest and most efficient capacity. From automated audits to procurement optimization, IRDS delivers actionable insights for modern warehouses.

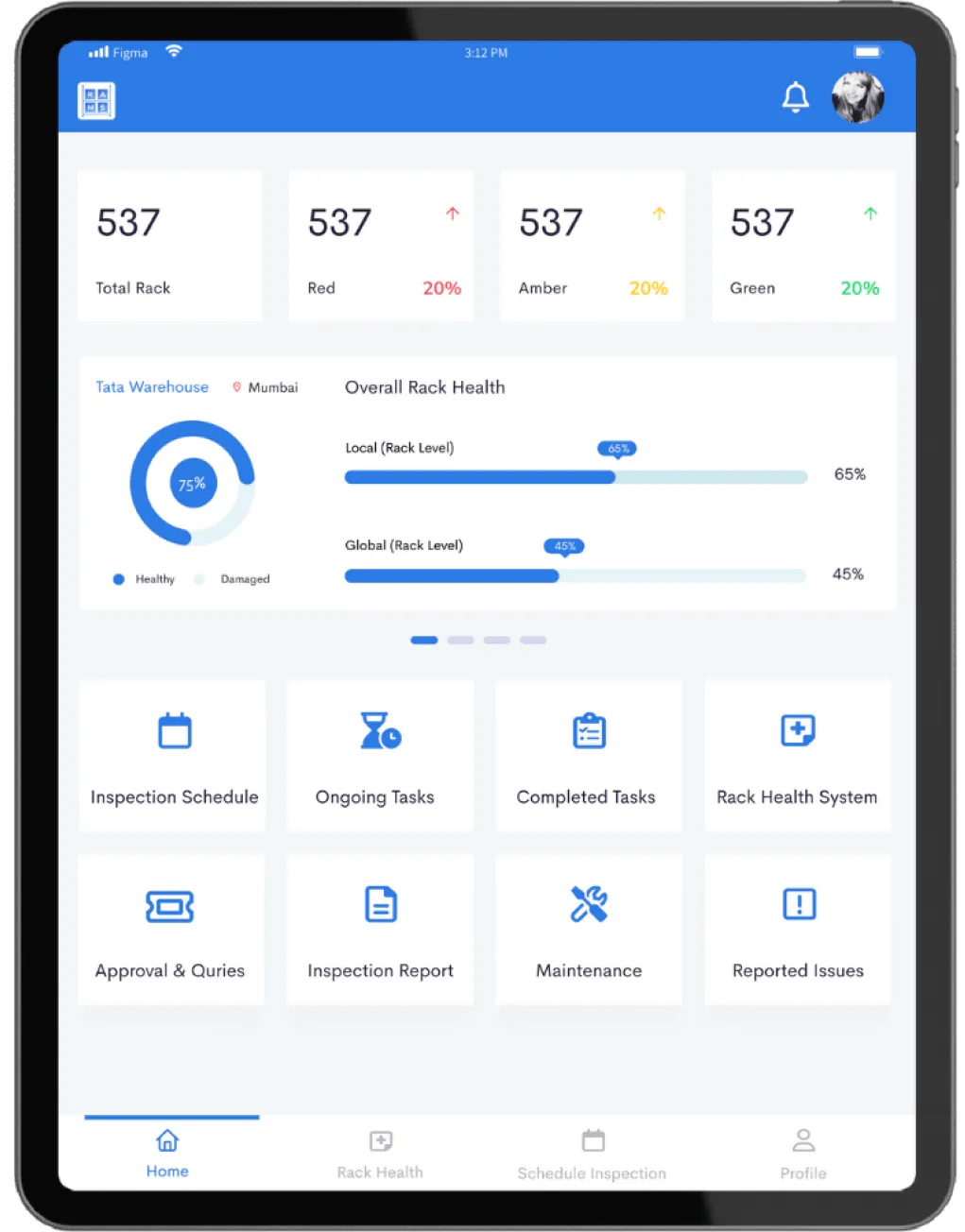

The Interactive Dashboard is designed to give you comprehensive control and real-time insights into your racking setup. Whether you’re managing multiple rack setups or overseeing a single project, our dashboard provides the tools you need to monitor progress, analyze data, and make informed decisions.

The dashboard displays total projects, ongoing projects, completed projects, and an inspection schedule, making it a central hub for managing warehouse operations efficiently. With real-time data and advanced features, it facilitates thorough inspections and ensures warehouse safety and compliance

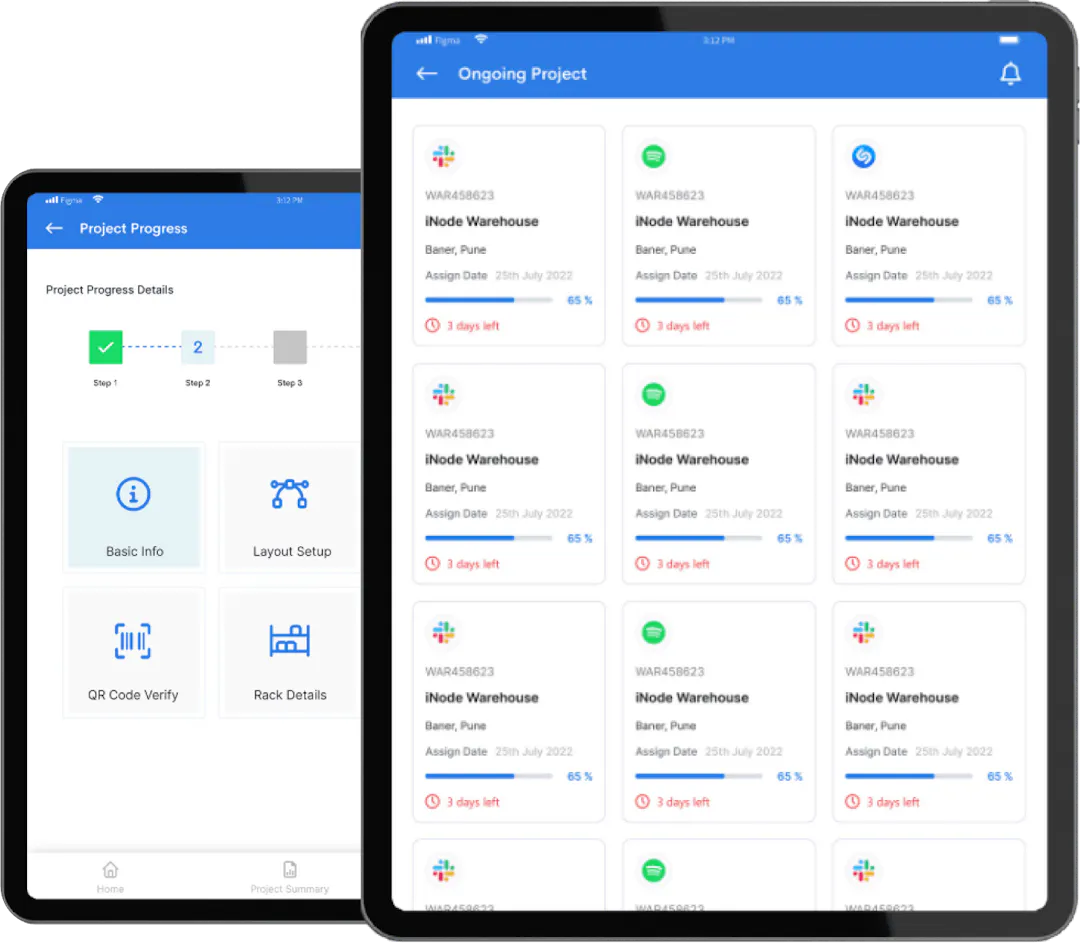

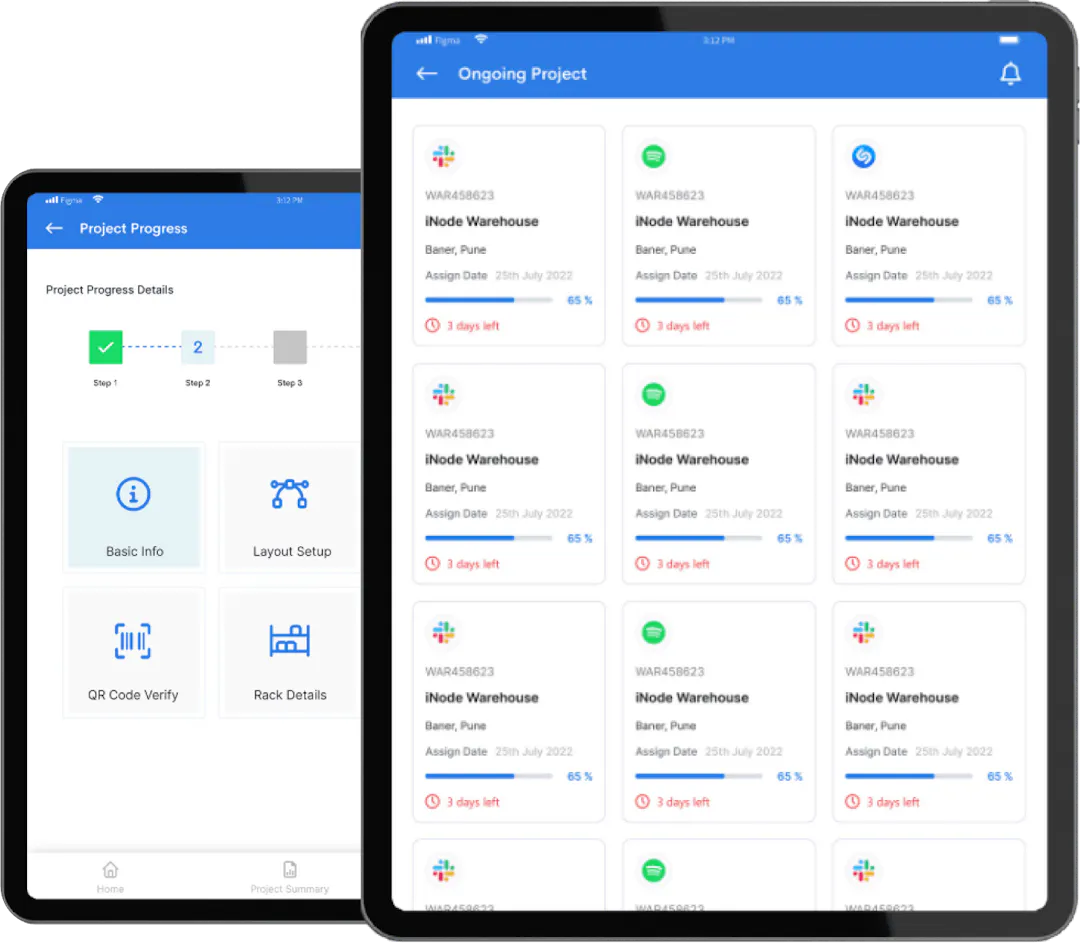

Efficiently manage your racking projects, warehouses or multiple sites with the Project Management portal.

Designed to handle multiple projects simultaneously, the portal provides real-time tracking and progress updates, ensuring you always have a clear view of your operations.

This feature enables the creation and assignment of tasks, setting deadlines, and monitoring progress on each project. Real-time updates ensure that any issues are promptly addressed, enhancing operational efficiency and ensuring all tasks are on track.

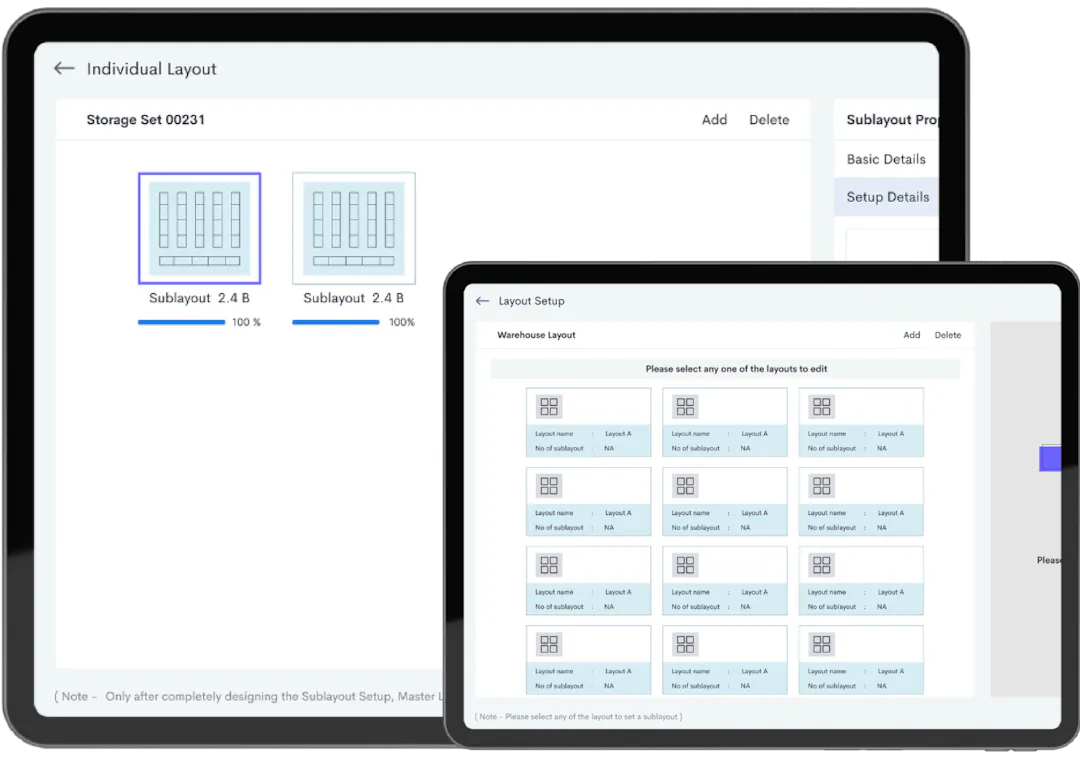

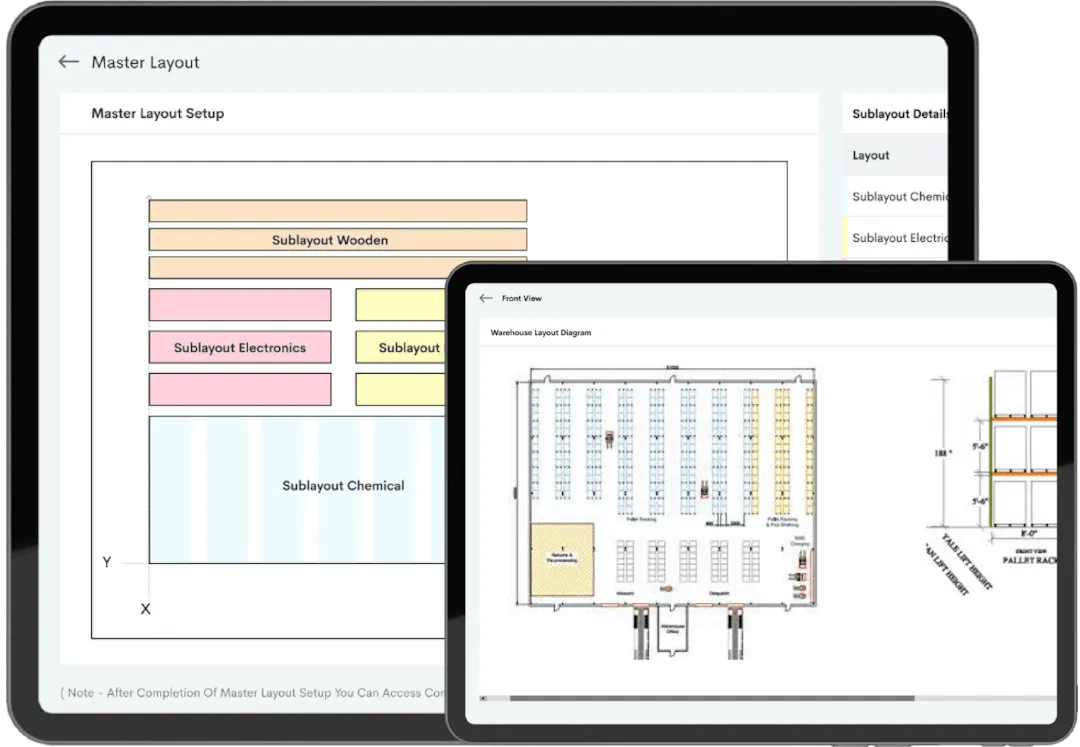

Optimize your warehouse operations with our advanced Warehouse Layout Setup feature. This tool allows you to create detailed digital layouts of your racking system, ensuring maximum efficiency and effective use of space. From accurate measurements to precise labeling, our layout setup feature can help you plan and execute the setup of your racking system with ease and precision.

This tool helps manage sub-layouts for multiple zones and setups, ensuring maximum efficiency and effective use of space. Precisely placing racks, aisles, and other features ensures the warehouse layout is optimized for safety and performance.

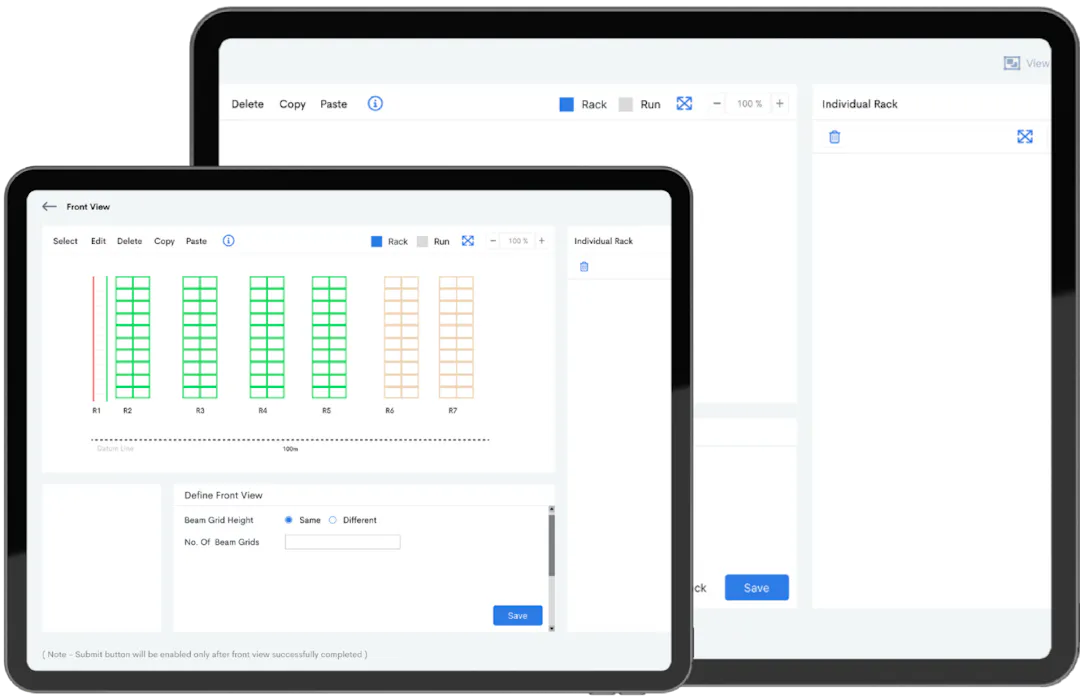

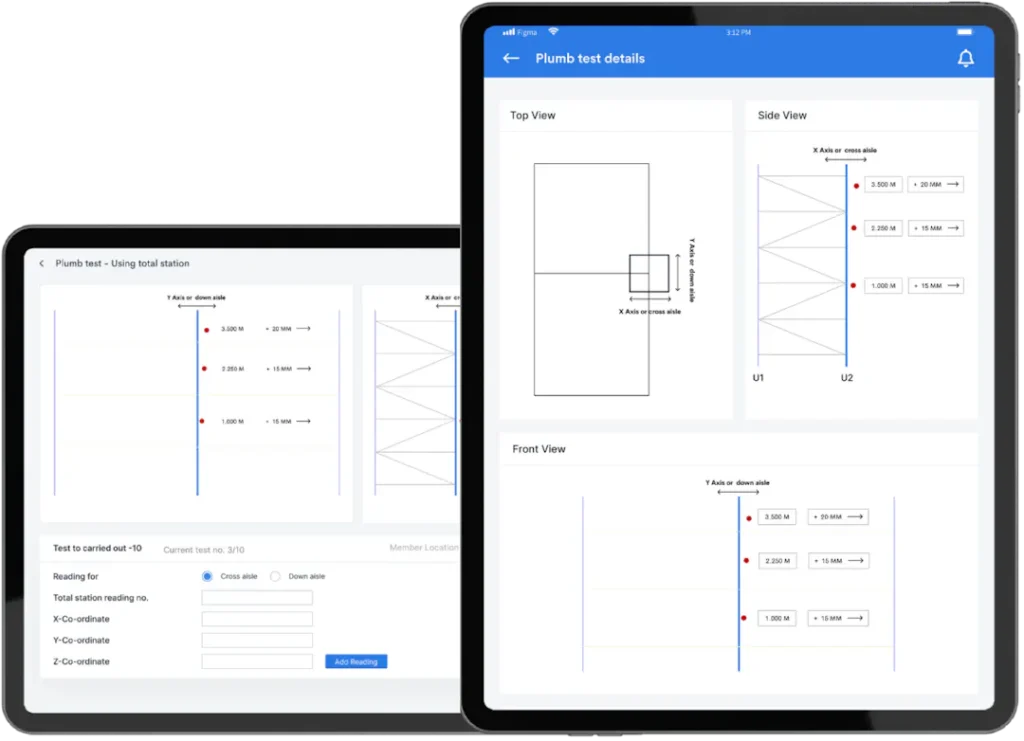

Our software allows you to create an accurate, detailed, and true-to-scale digital elevation of your entire racking system. This makes it easy to identify and detect issues to its exact location while inspecting to ensure that your racking system is safe and in compliance.

With the help of the digital racking system, you can streamline the planning and installation process, ensuring that every rack is correctly positioned and securely installed.

This makes it easy to identify and detect issues to its exact location while inspecting to ensure that your racking system is safe and in compliance.

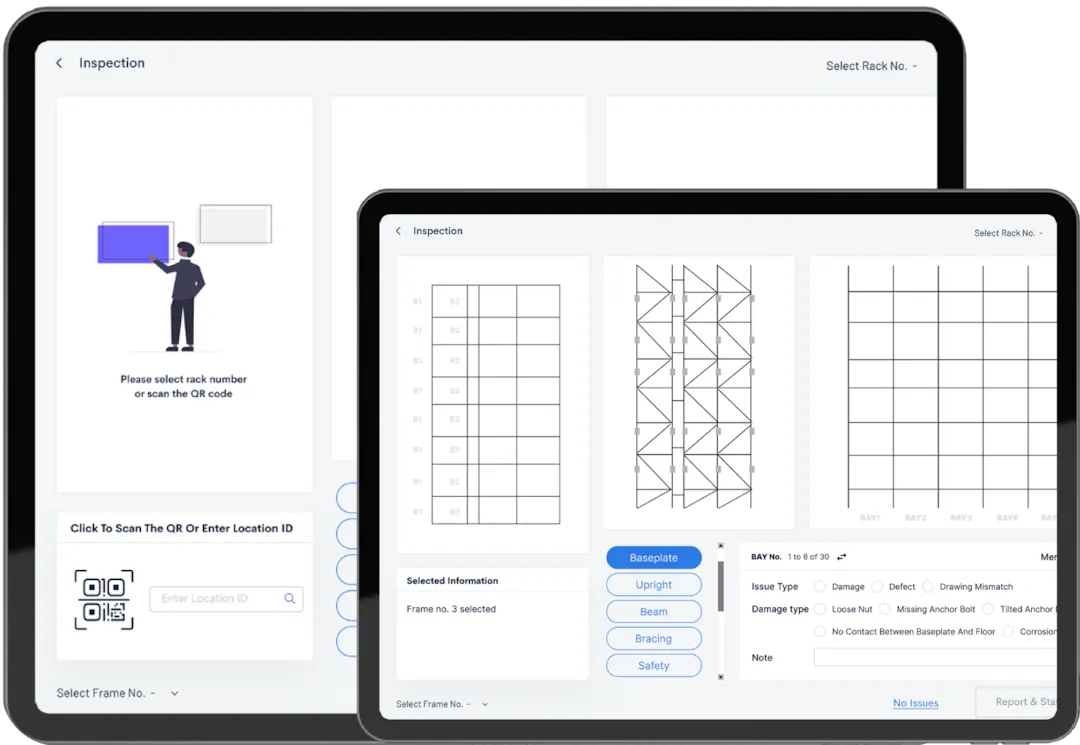

After Setup is complete, QR codes will be provided for labelling each Bay of racking, this will be used for the inspection process.

Ensure comprehensive oversight of your warehouse operations with our Master Layout feature. At the final step of your setup, you will receive a detailed master layout encompassing all components of your racking system in one cohesive view. This master layout allows you to precisely track issues to their exact location, enabling prompt action to address and resolve any potential problems.

With the Master Layout, you can prevent damage to your racking system, maintain operational efficiency, and ensure that your warehouse remains a safe and productive environment. This feature provides you with the necessary insights and control to manage your racking system effectively and proactively.

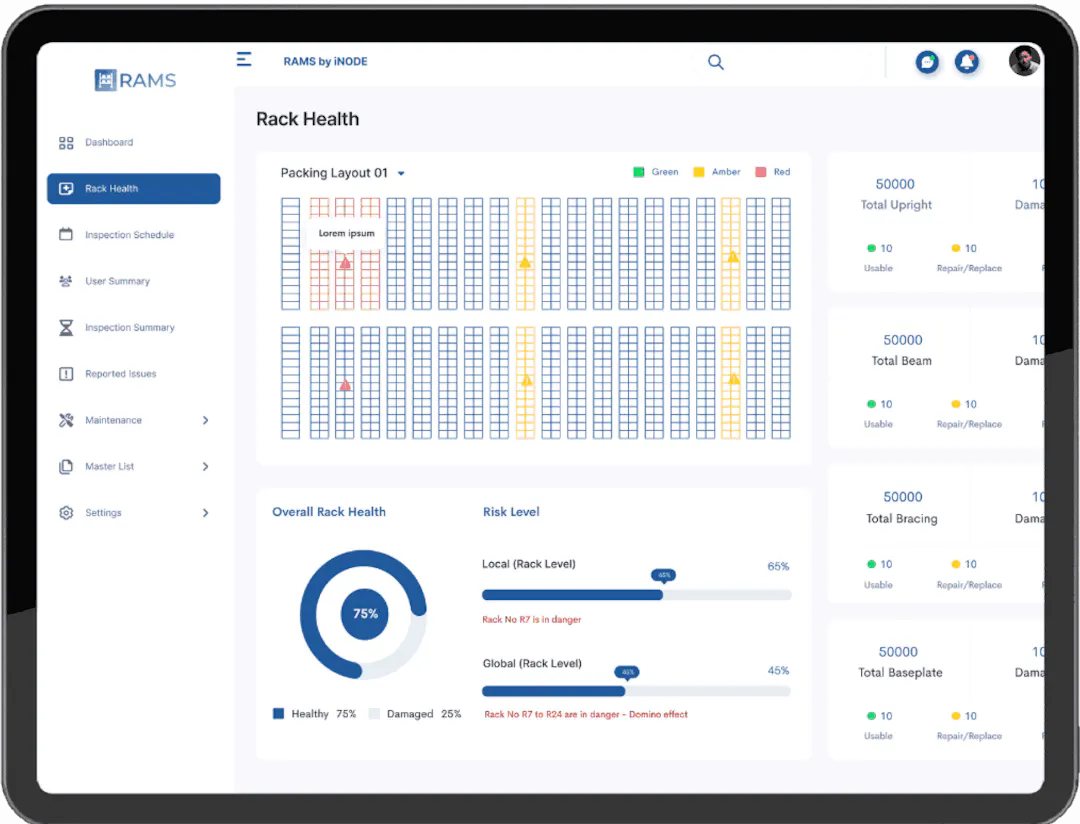

Monitor the health of your pallet racking system in real-time with RAMS software.

By analyzing detected issues, our system provides an accurate assessment of your rack health, presenting this critical information through an interactive and easy-to-understand dashboard.

This feature offers a clear and concise view of the current state of your racking system, highlighting areas that require attention. Additionally, with advanced predictive capabilities, our software enables you to foresee potential risks and address them proactively, ensuring the longevity and safety of your racking system.

Stay ahead of issues and maintain optimal rack health with real-time insights from RAMS.

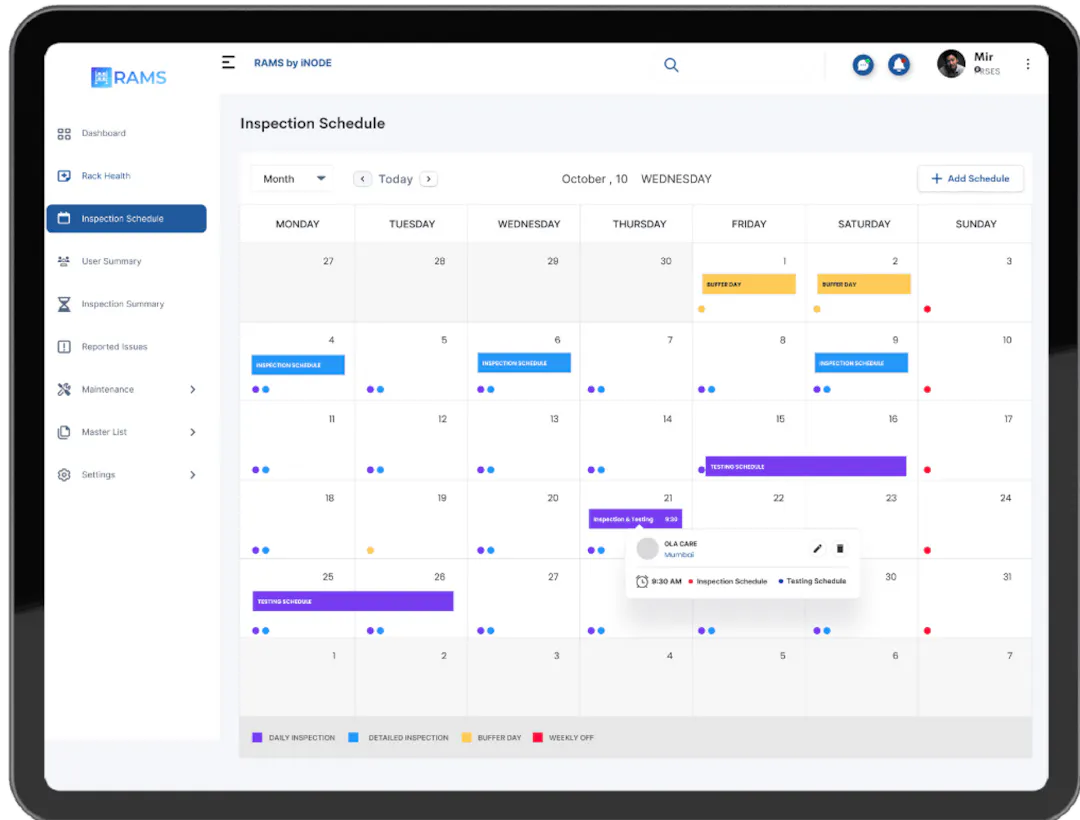

Efficiently manage and schedule your rack inspections, both Formal, and Informal.

The intuitive scheduling feature allows you to plan inspections, track progress, and generate comprehensive reports seamlessly.

The admin portal grants you full control over the entire inspection process, ensuring that all racks are inspected regularly. This proactive approach helps identify and address any issues promptly, maintaining the safety and integrity of your racking system.

With our scheduling tool, you can ensure a systematic and organized inspection routine, keeping your operations running smoothly.

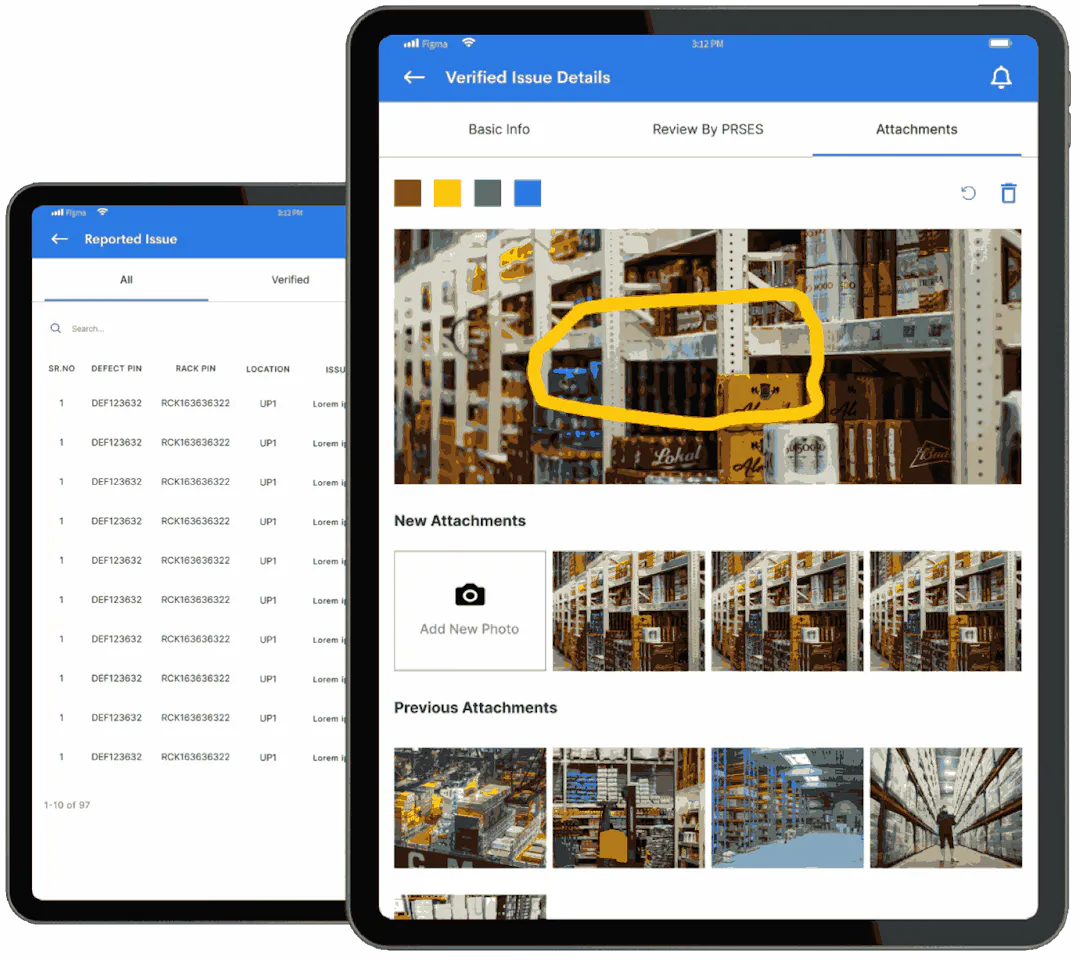

This feature allows for easy tracking and monitoring of any issues, ensuring timely maintenance. Include Severity, Type, Location, Notes, Images and rectifications all in one place. Incredible Records when needed

By monitoring the health of your racking systems, you can proactively address potential problems before they escalate, maintaining the efficiency and safety of your warehouse operations.

RAMS real-time damage issue tracking ensures your warehouse runs smoothly with minimal disruptions.

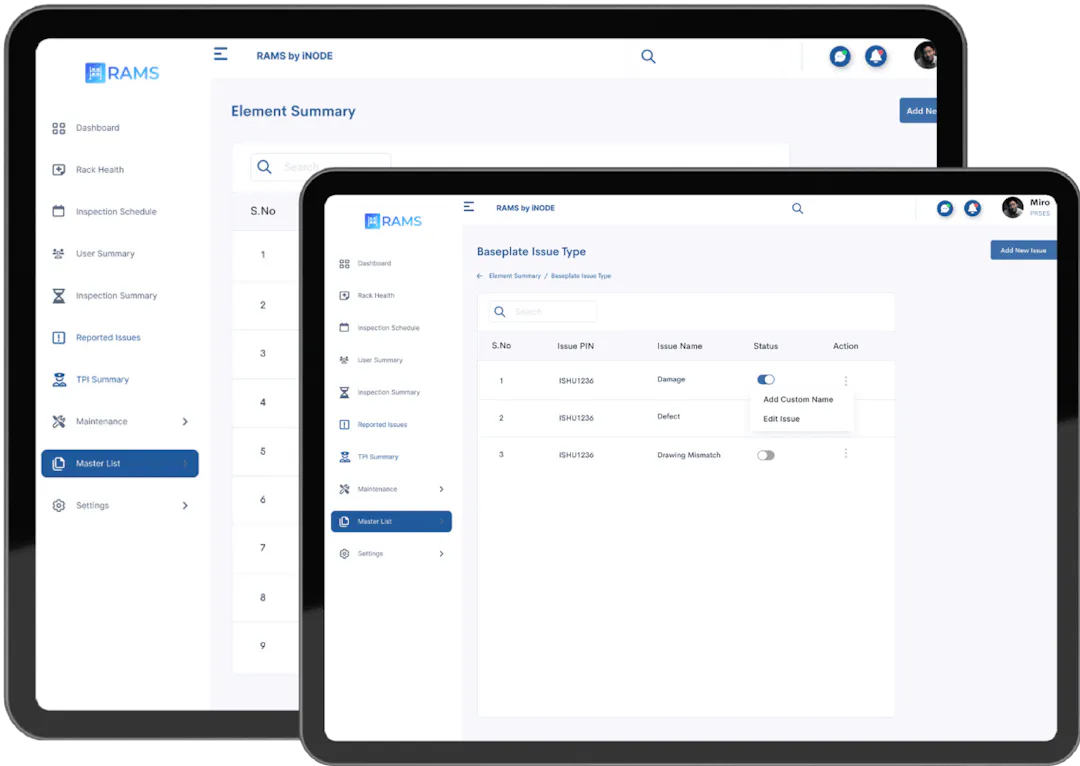

RAMS offers the flexibility to customise your checklist and pallet rack elements to best fit your team’s needs. This feature allows you to design a solution that maximizes efficiency and organization in your warehouse and inspections.

With a customised checklist, you can ensure that every inspection and maintenance task is tailored to your specific requirements, improving accuracy and accountability.

By adapting the system to your unique workflow, you can streamline operations, reduce errors, and enhance overall productivity.

The Formal Third-Party Inspection (TPI) and informal reports are seamlessly integrated into RAMS, providing real-time updates on the inspection status and current condition of your pallet rack systems. This feature allows for easy tracking and monitoring of inspections conducted by the TPI, ensuring that you are always aware of the health and safety of your racking systems.

By leveraging expert third-party insights, you can gain a more comprehensive understanding of your racking system’s compliance with industry standards and identify potential issues before they become critical. Our platform ensures that you receive timely and accurate information, enabling you to maintain a safe and efficient warehouse environment.

RAMS also ensures that no steps are skipped in the inspection process. If you book a new TPI and are unsure of their skill, RAMS will guide them through the warehouse step by step. This guarantees that all necessary checks are performed thoroughly and accurately, maintaining the highest standards of safety and compliance.

The TPI Inspection process includes an in-depth audit and inspection of your pallet rack systems after the initial informal inspection. The TPI will identify any issues and provide solutions to ensure the safety and optimal performance of your warehouse operations. This approach ensures that any issues are thoroughly addressed, minimizing the risk of accidents and downtime.

With RAMS, you gain peace of mind knowing that your racking system is inspected and maintained to the highest standards, keeping your operations safe and efficient.

Reporting an issue with your pallet rack system has never been easier. With the help of RAMS, you can complete the process in just three simple steps:

Our streamlined issue reporting process ensures that you can maintain the integrity and safety of your racking system with minimal effort.

By simplifying the steps, RAMS allows you to focus on what matters most – running your warehouse operations.

RAMS allows you to easily manage all previous and current issues. With the ability to track the status of each issue, you can quickly determine if it has been resolved or if further attention is needed. This real-time monitoring ensures timely resolution of any issues, keeping your inspections running smoothly and your racking system in optimal condition.

By providing a comprehensive overview of reported issues, RAMS helps you maintain a proactive approach to rack management. Stay informed, stay efficient, and keep your warehouse operations on track with our advanced issue management capabilities.

Transform your warehouse into a fully digitalized environment with precise tracking and management capabilities

While online syncing is required, RAMS does not need internet acces during digitisation or inspection.

Identify and address impacts on your racking system in real time to prevent damage and ensure safety.

Enhance the safety of your warehouse with advanced monitoring and proactive maintenance scheduling

Monitor the health of your entire racking system in real-time to ensure optimal performance and safety

Lorem ipsum dolor sit orot amet, cons ctetur atrd piing elit.

Access reports on your racking system's condition and maintenance needs at any time

Streamline your inspection process with digitized scheduling, tracking, and reporting.

We generated .std files for a visual representation and structural analysis of the rack system.

Gain complete control over your warehouse operations with real-time data and advanced management tools

Rack Elements and Checklist are customisable as standard with other customisations to be discussed.

The software tracks and monitors rack system damage, helping you anticipate potential hazards and take necessary measures

Digitising your warehouse is the first step towards modernizing and streamlining your operations. By creating a digital twin of your racking system using RAMS, you can accurately model the racks to scale and assign manufacturer specifications to individual components. This setup not only helps in monitoring the health of your racking system but also simplifies maintenance and procurement activities by providing a comprehensive and detailed digital representation of your storage infrastructure.

Incorporating customisations and IoT into your warehouse setup can significantly enhance efficiency and operational capabilities. Customisation options within RAMS allow you to tailor the system to meet specific needs, ensuring that all unique requirements are addressed. Integrating IoT devices can provide real-time data on the condition and usage of your racking system, enabling proactive maintenance and better decision-making. This integration ensures that your warehouse operations remain cutting-edge and responsive to any issues as they arise.

Regular inspections are crucial for maintaining the safety and integrity of your racking system. RAMS facilitates both formal and informal inspections through its user-friendly interface, enabling quick and thorough evaluations of your storage infrastructure. Internal inspectors can conduct detailed examinations using a tablet-based app, while the PRSES oversees the process, verifying issues and suggesting actions based on RAMS data. This systematic approach ensures that any potential problems are identified and addressed promptly, maintaining high safety and compliance standards in your warehouse.

Typically, it is based on an annual subscription model, with options for per-user pricing, usage-based pricing, or bundled pricing.

Yes, we provide a free online demo of the software.

You can access the digitisation software from your laptop, PC, and tablet.

The inspection Application is currently Android Only and it is recommended to use a tablet

Customized solutions are offered with respect to rack elements and checklists.

No.

RAMS does however help to ensure you meet the minimum standards, It will always be up to the inspector to ensure that the overall design meets current standards and is installed correctly, and hasn’t been modified without manufacturer or designer approval

Training is currently managed on a case-by-case basis while we grow in Australia. Online training is available, and courses are in development.