Why Compliance is More Than Just an Inspection

Pallet racking safety is critical to warehouse operations, yet many businesses believe that a routine visual inspection is enough to keep them compliant with Australian Standards.

The reality? Inspections are just one piece of the puzzle.

Compliance is not just about ticking a box—it’s about proactively managing risk, tracking repairs, and maintaining a high standard of safety throughout the year.

The Key Differences Between Inspections and Compliance

1. Inspections: The Snapshot Approach

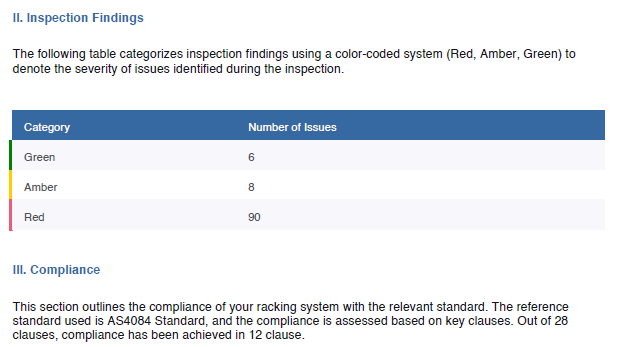

Warehouse racking inspections are designed to assess the current physical condition of your storage system. They identify visible damage, misalignment, structural and safety issues.

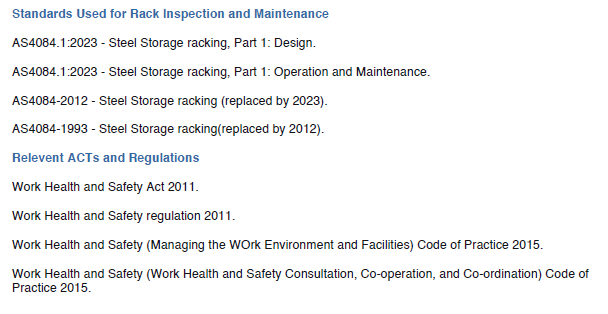

🔸 Professional Annual Inspections: A trained expert evaluates your racking against industry standards (such as AS4084:2023) and flags any concerns. This includes your signage, engineering, elevations, MHE, environment and procedures.

🔸 Internal Inspections: Regular checks by warehouse staff or third party inspectors help catch physical issues before they become serious problems.

🔸 Issue Identification: An inspection highlights damage, improper loading, and other risks, but doesn’t necessarily ensure they get fixed.

📌 The Limitation: A once-a-year inspection report doesn’t guarantee that repairs are made, load limits are followed, or safety processes are maintained in daily operations.

2. Compliance: A Continuous Process

Being compliant means more than identifying risks – it means actively managing them. Compliance involves structured processes, proper documentation, and ongoing maintenance to ensure the warehouse always remains safe.

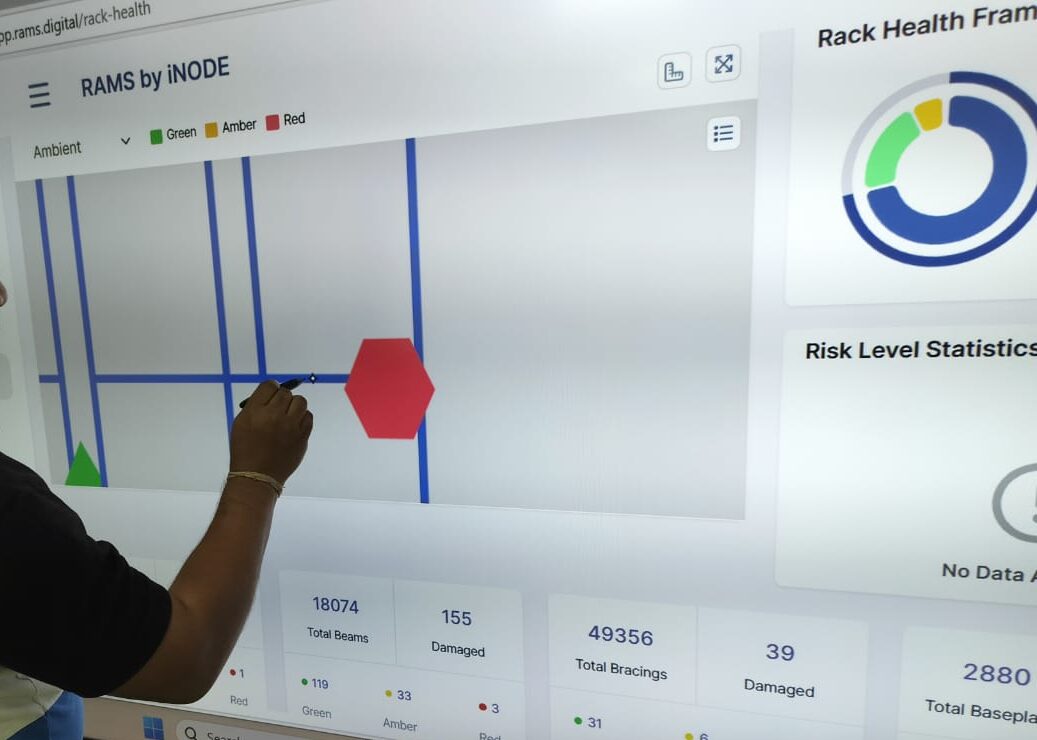

✅ Structured Inspection Management: Tools like RAMS IRDS (Integrated Rack Diagnostic Suite)ensure that every inspection follows a standardized process.

✅ Digital Issue Tracking: Compliance systems track the progress of reported issues, ensuring they are identified AND Resolved.

✅ Load Capacity & Safe Use Monitoring:Recording how racking is used to ensure it aligns with manufacturer guidelines, industry standards and safe work practices.

✅ Training & Policy Enforcement: Compliance ensures that employees understand racking safety protocols, reducing human errors. Training on reading a load sign, safe loading and unloading procedures, and packing a pallet for secure storage.

✅ Audit-Ready Documentation: With a compliance system, your business is always prepared for Worksafe visits, audits, and reducing liability risks.

⭐Bonus: Use it to reduce your insurance premiums

📌 The Key Takeaway: Compliance is a continuous process, not a one-time event. It ensures that safety standards are upheld between inspections, rather than reacting to problems only when an inspector arrives.

Why PRMS is a Compliance Solution, Not an Inspection Tool

At PRMS, we provide more than just a way to conduct inspections—we offer a complete compliance management system. The RAMS platform ensures that every inspection feeds into a larger compliance framework, allowing businesses to track issues, verify repairs, and maintain a safety culture.

🔸 IRDS: Standardised digital inspection tracking for consistency and accuracy.

🔸 Real-Time Reporting: Log and track repairs to ensure nothing is overlooked.

🔸 Multi-Site Management: Keep compliance records organized across multiple locations.

🔸 Customizable Workflows: Tailor compliance processes to meet your warehouse’s specific needs.

By shifting the focus from reactive inspections to proactive compliance, businesses can reduce safety risks, lower costs, and create a more efficient warehouse environment.

Compliance is the Future of Racking Safety

While inspections will always be essential to racking safety, they should not be the only safety measure in place. Businesses that take compliance seriously go beyond inspections, ensuring that risks are managed, safety is enforced, and rack integrity is maintained year-round.

Are you still relying solely on annual inspections?

Are your reports provided from an Excel template or a checklist form?

It’s time to upgrade to a real compliance solution.