Are you sure your racking systems are up to code?

In the fast-paced world of warehousing and logistics, racking systems are the silent workhorses that keep operations moving smoothly. They bear the weight of your inventory, support efficient workflows, and play a vital role in maintaining safety standards. Are you giving these essential structures the attention they deserve?

If your racking systems aren’t regularly inspected and maintained, you might be sitting on a ticking time bomb — both for your safety record and your bottom line.

Why Regular Racking Inspections Are Essential

In Australia, compliance with racking standards isn’t just a best practice; it’s a WHS requirement. According to the Australian Standard AS4084.2:2023, regular inspections are mandatory to ensure the safe use and maintenance of steel storage racking. But beyond ticking off compliance boxes, here’s why you should take racking inspections seriously:

1. Compliance: It’s the Minimum Standard, Not an Option

Under AS4084, all businesses using racking systems must conduct formal inspections at least once a year. Failing to do so could result in hefty fines and legal action if an incident occurs. In severe cases, businesses could face penalties or even industrial manslaughter charges if found negligent. Recently, a local business faced over $375,000 in fines for a racking incident involving a unit just 3.6m tall—a reminder that even smaller setups are not immune to risk.

2. Safety: Protect Your Most Valuable Assets

Your people are your most valuable assets, and their safety should be non-negotiable. Regular racking inspections help identify potential hazards—like bent beams, loose connections, or overloaded racks—before they cause accidents. A single collapsed rack could result in severe injuries, damage to goods, or even fatalities. Ensuring that your racking is up to code is a simple yet powerful way to protect your team and your business.

Think about it—how confident are you that your racking is safe and compliant? Please don’t wait until it’s too late.

3. Cost Savings: Prevention is Better Than Cure

Neglecting regular inspections could lead to significant financial setbacks. Unnoticed damage can deteriorate further, resulting in costly repairs or even complete racking replacements. By catching issues early, inspections help avoid these unnecessary expenses. Plus, a well-maintained racking system minimizes downtime, keeping your operations running smoothly and efficiently.

4. Operational Efficiency: Keep the Wheels Turning

A disruption in your racking system can cause a domino effect, halting operations, delaying deliveries, and frustrating customers. Regular inspections ensure that everything is in tip-top shape, reducing the likelihood of unexpected breakdowns. This proactive approach supports continuous operations, enhances efficiency, and ultimately boosts your bottom line.

Key Questions About Racking Inspections

- How Often Should You Inspect Your Racking? A formal inspection must be conducted annually at a minimum. However, businesses in high-traffic environments or those experiencing heavy usage may need to schedule more frequent formal inspections. Daily visual checks and weekly or monthly informal inspections are good practices to adopt. A competent person should determine your frequency and perform your formal inspections.

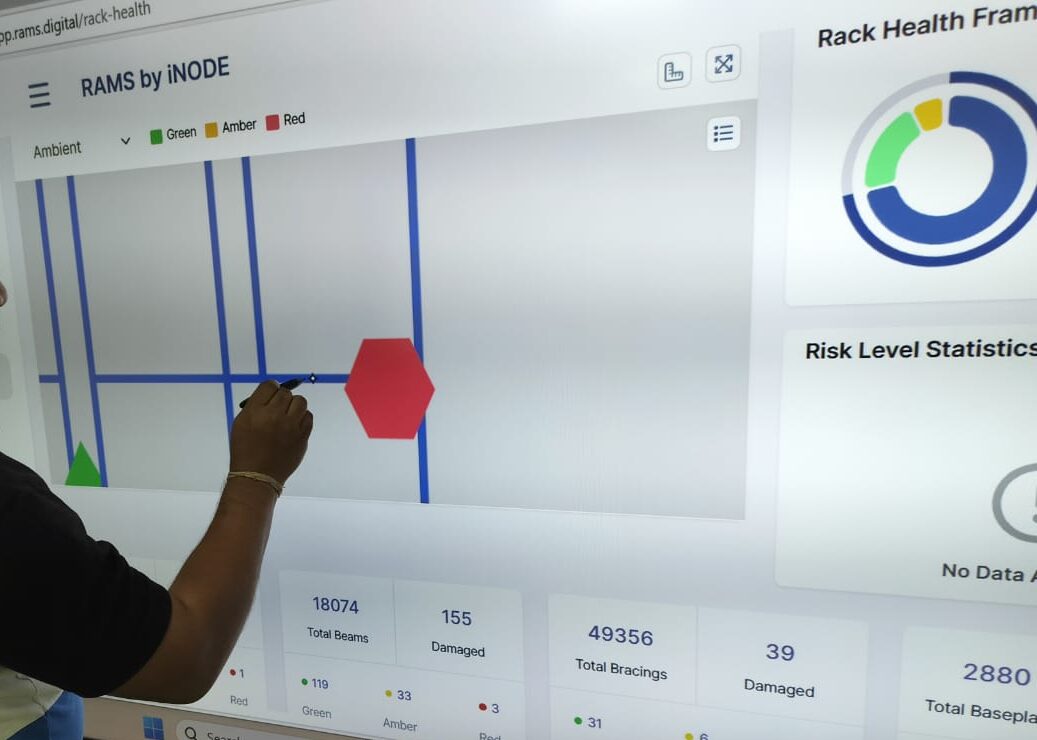

- What Do Inspectors Look For?Inspectors evaluate the condition of beams, columns, braces, and connectors. They also check for proper load distribution, the status of safety accessories, and any visible signs of wear or damage. The goal is to identify and rectify potential safety hazards before they escalate. Not only that, but they must also ensure all your design is correct, that the required paperwork has been provided, and that you know how to take care of your racking system.

- Can Inspections Help Prevent Accidents? Absolutely! Regular inspections help detect signs of damage or fatigue that could lead to accidents. By identifying these early, you significantly reduce the risk of rack failure, ensuring a safer working environment for everyone.

- Is It Necessary to Document Inspections? Yes, keeping records of all inspections is vital for tracking compliance, monitoring racking conditions, and ensuring a prompt response to any issues. Proper documentation also provides a clear trail of accountability, proving that your business takes its safety obligations seriously.

Empowering Your Team with Training and Awareness

It’s not just about hiring a qualified inspector—your team plays a critical role in maintaining racking safety too. Educating your staff on safe loading practices, recognizing early signs of damage, and understanding load capacities can prevent accidents long before they could happen. A proactive safety culture begins with well-trained employees who know the risks and how to mitigate them.

Don’t Wait—Take Action Now

Regular inspections not only help you stay compliant with AS4084.2:2023, but they also protect your staff, reduce costs, and maintain operational efficiency—ensuring your business stays ahead.

Don’t leave safety to chance.

Schedule your racking inspection with SSO today and ensure a safer, more compliant warehouse environment.

At SSO Handling & Storage, we offer comprehensive racking inspection services by Experienced, Competent professionals who understand the nuances of AS4084 compliance and have experience with all major brands. We’re here to help you identify risks, stay compliant, and keep your warehouse running smoothly.

Reach out today to schedule your inspection or get more information on how we can support your business.